just in case – organising procurement to ensure that the production process never runs out of stock

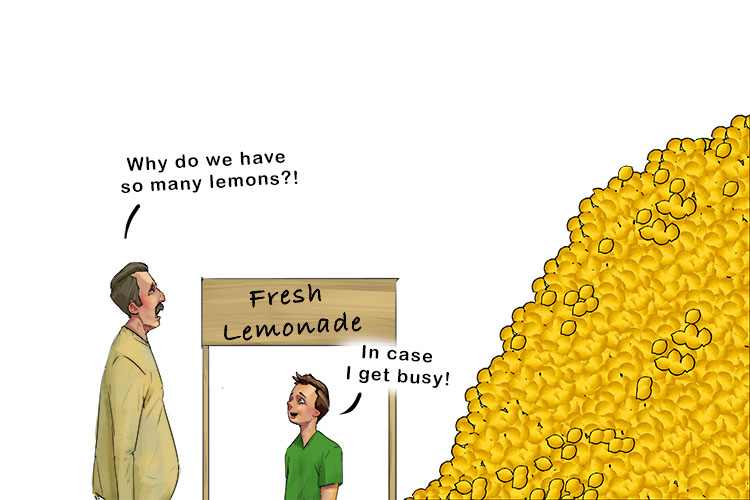

To remember what just in case means use the following mnemonic:

Just in case (just in case) the business has an increase in demand, we organise procurement to ensure we never run out of stock.

The just in case (JIC) inventory strategy differs from the just in time (JIT) inventory strategy, where companies attempt to minimise inventory costs by ensuring materials only arrive when they are needed for production. In contrast, ‘just in case’ involves keeping a large amount of stock on hand. This strategy is usually more common in less developed nations in which the transport infrastructure cannot support a strategy of regular, smaller deliveries. It is also common with companies that struggle to predict consumer demand and so stockpile goods to prevent ever being sold out. If a company is able to find a great bulk deal on a product and save a considerable amount of money, then this could be a reason to stockpile goods and adopt a just in case inventory strategy.

Some examples of when a just in case inventory strategy might be appropriate:

• A company that sells seasonal products, such as Christmas decorations, might want to keep a large inventory on hand in the months leading up to the holiday season in order to avoid running out of stock.

• A company that manufactures a product that is used in a variety of other products, such as a component that is used in cars, might want to keep a large inventory on hand in case there is a disruption in the supply chain for that component.

• A company that sells a product that is in high demand, such as a new video game, might want to keep a large inventory on hand in order to meet the demand of customers.