Procurement – Buying products that suit the strategic fit for the business, not just the cheapest

(Pronounced pruh-kyor-muhnt)

To remember what procurement means use the following mnemonic:

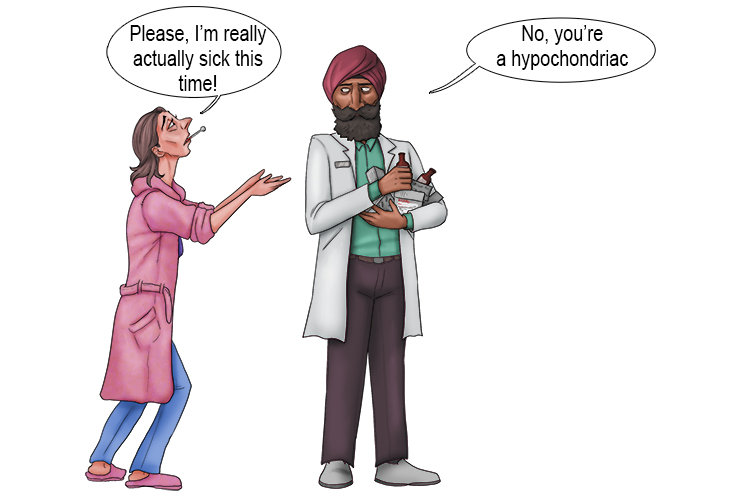

The pharmacist provides cures for payment (procurement) but believes it's not the best strategy to sell to this customer.

There is a massive difference between procurement and buying. Anyone can buy the cheapest product for a company, but is it the correct purchase?

A professional procurement manager or purchasing manager analyses the best strategic purchase for each product. The best way to show the difference is to discuss several examples.

Furniture supplier example

The joinery shop making furniture had always purchased complete planks of oak straight from the sawmill and used them to build their furniture. The managing director decided to take on a procurement/buying manager who had an immediate impact. After the procurement manager assessed the potential suppliers and analysed the customer base, she convinced the managing director to buy engineered oak instead. She said a thick leg for a table could be made of poor-quality inner core oak but a very high-quality 3mm veneer oak glued to the outside edge. The table could still be advertised as all oak tables but could be sold a lot cheaper. In addition, each supply of veneered oak would be perfect, unlike the oak planks where there is a lot of wastage due to splits, large colour variation or too many knots. This made a dramatic improvement in production because less storage was required of large solid planks and very few processing machines were required.

Car parts supplier example

A car assembly plant had very little space and required components for the car to arrive shortly before they needed them (just in time manufacturing). The procurement manager changed the exhaust pipe supplier to another more expensive company. When the managing director asked why, the procurement manager said that the new supplier fitted the company’s strategy better and that they would save more money in the future. The last supplier didn’t always supply when required. When the factory had to wait for one hour for the exhausts to arrive, it cost 30 assemblers 1 hour each. At a factory production cost of £100/hour per person, this meant the loss amounted to £3000 (30 x 100 = 3000). The new supplier at only a slightly higher cost would never cause this loss.